LEANTEC

LEANTEC  1707

1707

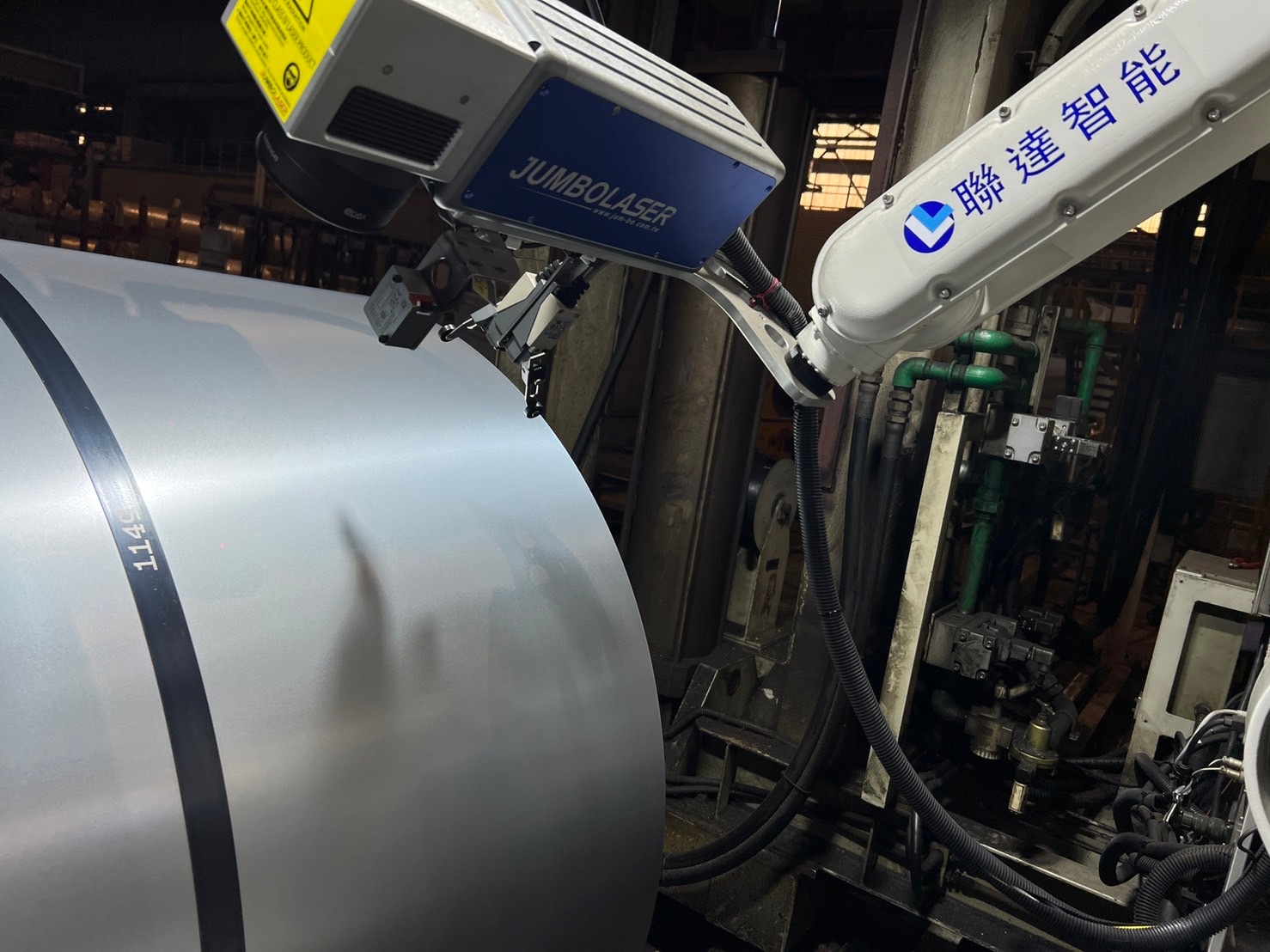

Taiwanese largest integrated steel maker, with an annual production capacity of up to 16 million tons, is actively moving towards zero-carbon processes in the face of the global ESG trend. Without compromising production capacity and maintaining stable quality, introducing six-axis robotic arms has successfully overcome technical bottlenecks associated with large-scale steel coil laser marking.

In conventional practices, the customer has traditionally relied on manual writing or inkjet printing to mark numbers on the outer circumference of steel coils to avoid mixing issues. However, this method presents several challenges, including high ink consumption, frequent maintenance requirements, and the complexity of ink removal. Additionally, the failure to ensure a clear surface for steel coils often results in the removal of entire coil strips with marked areas, causing material losses and an overall escalation in procurement costs for customers.

In a groundbreaking collaboration between Leantec's Intelligent Team and Jumbo Laser, the customer is now incorporating Leantec's C Series six-axis robot arms. These advanced robotic arms seamlessly interface with cutting-edge technologies, including laser marking systems, visual-inertial cameras, and Laser Measurement Systems, forming an intelligent positioning system. This innovative integration offers an industry-specific process package, facilitating the accurate marking of identification numbers on steel coils.

Leantec robot arm, equipped with a vision for automatic positioning, exhibits remarkable flexibility to adapt to various steel coil sizes, achieving unparalleled production flexibility. Featuring Syntec technology controller within the machine, the system offers user-friendly programming through dialogue programming, along with three major customizable tool platforms to cater to diverse user application needs.

The advantages of laser marking, including high speed, stable power, and a long lifecycle, perfectly address issues related to material loss and environmental pollution inherent in traditional marking methods. The Leantec robotic arm, coupled with its advanced controller, boasts highly integrated capabilities, offering solutions ranging from path planning and compensation to industrial communication. This results in a substantial reduction in the integration development timeline for automation applications.

This Syntec-centric solution, complemented by various value-added features, facilitates a seamless upgrade for clients and lowers the threshold for intelligent transformation in factories.

Click the button below for more on how to reshape the landscape of smart manufacturing in the industry.

Recommend products:

Leantec C Series Six-axis Robotic Arm

710SA High-level Serial Marking Controller