LEANTEC

LEANTEC  1666

1666

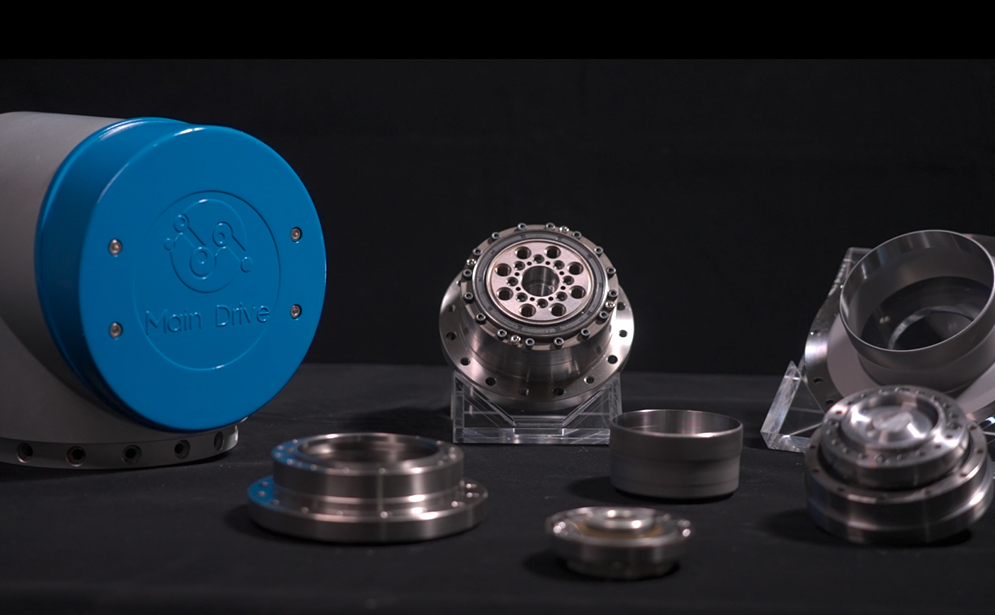

MAIN DRIVE specializes in the development, design, and manufacturing of harmonic speed reducers and has earned ISO9001 quality certification, gaining the trust from customers. In addition to investing substantial energy in R&D and obtaining numerous patent certifications, Main Drive also allocates significant resources to advanced processing techniques, ensuring superior quality and production efficiency.

▲ Main Drive's Harmonic speed reducer and its key components

However, in the pursuit of higher standard products, Main Drive faces severe challenges in production and quality management.

Internally, challenges such as lack of transparency in production status and capacity, information gaps due to untimely reporting, and a lack of systematic integration arise. Externally, frequent order changes cause chaotic scheduling. Additionally, tracking serial numbers for in-house production items, finished products, and outsourced workpieces is problematic, as it cannot be integrated, making product identification and differentiation difficult.

In quality management, manual measurement and data inputing are common, followed by manual input, which is time-consuming and error-prone. The variety of inspection instruments and their different file formats complicate data analysis. Machine-side measurements are also manually recorded and calculated, leading to potential errors.

Production Management Module and Quality Inspection Management Module of Leantec SynFactory are specifically designed for the metal processing industry. These modules offer comprehensive functions and flexible design that can be adjusted according to different scenario and stakeholder perspectives. In this case, Leantec acted as a consultant, collaborating with the client to identify and prioritize pain points in the production process. Through phased implementation, Leantec helped Main Drive quickly achieve its smart factory vision.

Leantec SynFactory integrates OT and IT information, achieving real-time production monitoring and enhanced quality management. This empowers manufacturing with automation, smooth operations, and data-driven capabilities, significantly strengthening manufacturing resilience.

1.80% reduction in the tracking time of manual production progress: The system provides real-time utilization rates and production progress, enabling production management personnel to accurately estimate scheduling.

2. 95% reduction in work order filling and reporting time: The system integrates process information, allowing for quick application to work orders.

3. Serial number tracking: Offer the function of setting various serial number, combining BOM serial numbers to establish parent-child relationships, facilitating subsequent tracking of production and quality conditions.

4. Automatic summarization of inspection records: Quickly consolidates precise analytical data such as SPC and quality yield rates, reducing the time spent on manual data compilation and analysis.

5. Digitalization of measurement data: Automatically identifies inspection results at each station, avoiding manual errors.